At Sedef, we need energy during our production processes to cool the meat and assure the quality and food safety of our products. Approximately 40% of the electricity we use is for this purpose. Our energy contracts are evaluated every year with the aim of reducing production costs. If different suppliers are similar in price, we look at the energy mix of the provider (proportions of renewable and non-renewable).

We do everything we can to minimise our energy consumption without compromising product quality and food safety

We are committed to limiting energy use as much as possible, but without compromising product quality and food safety. To that end, we work on energy saving measures. All production sites submit monthly reports on energy efficiency, which are benchmarked against best practices. When sites show a wide divergence from the benchmark, we focus on how to reduce the energy consumption there.

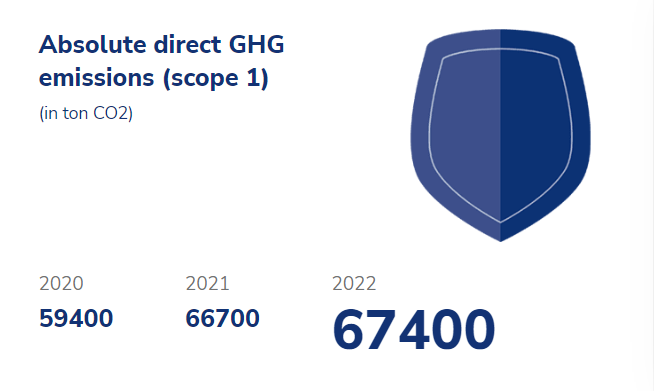

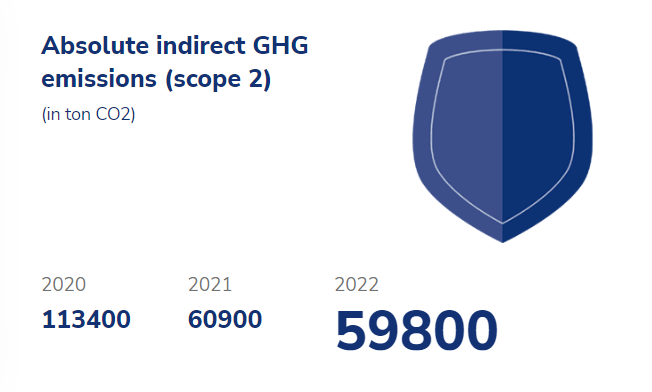

Our objective for 2022 is to decrease our Scope 1 + 2 CO2e emissions per tonne sold from 88 to 84. Reductions in energy usage will not only be achieved by increasing energy efficiency and applying the latest techniques, but also by structurally changing our consumption model.

In 2024, we will have six electric terminal tractors in operation

Cooling

Since cooling takes up the biggest part of our energy usage, using approximately 40% of all electricity demand, we are focusing on ways to make the cooling process more energy efficient. In addition to the spray cooling system used to cool carcasses and a programme to optimise the cooling temperature per room and per moment, we are investing in modernising our cooling system at approximately 10 sites.

Re-utilising released energy

We are also always looking for ways to reutilise released energy. In 2021, we began evaluating the concept of converting slaughterhouse waste into biogas to power our fleet and ensure long-term, profitable independency in logistics and the energy sector. This evaluation will be finalised in 2022.

Scopes 1 and 2

In 2022, we reduced our absolute scope 1 and 2 emissions compared to 2021. However, production volumes also shrank, which had a negative impact on our relative KPI (emission per volume).

For the calculation of our scope 1 GHG emissions, we took into account:

Our scope 2 emissions are based on our purchased electricity consumption and the location-based method. The organisational boundary is set based on financial control. The sources for the CO2-emission factors used to calculate the CO2-equivalents are:

– for electricity use in Germany and Belgium https://ghgprotocol.org/ghg-emissions-calculation-tool,

– for all other emission factors https://co2emissiefactoren.nl/.

Carbon footprint of food products

Within the consumption of food of animal origin, consuming pork and poultry from the Netherlands and Germany is a relatively climate-friendly way to meet consumers’ protein needs because of meat’s high nutritional value. This meat has a similar CO2 footprint per 100 g protein to tofu (see figure), although its nutritional value for humans is much higher. At the moment, we are calculating our total scope 3 emissions and plan to publish these in our next report.

© 2010 – 2023 Sedef SA. All right reserved.