Sedef understands the challenges of ensuring traceability in complex supply chains for companies that produce food items. We are committed to ensuring transparency in traceability. We document and provide traceability information for all our plant products and non-animal ingredients processed at Sedef, both in hardcopy and digital formats. All our meat and processed products can be traced back to the day of slaughter and the group of farms that supplied the animals.

For our retail customers, we include a traceability code on the package, indicating the farm that supplies that specific retailer. Consumers can scan a QR code to view information on where the product was produced, at which plant the animal was slaughtered, and when it occurred.

All our food items derived from either plants or animals are traceable to the farms

Managing a trustworthy chain of custody and ensuring that the product matches the label is crucial for product integrity. This involves organizing product and process integrity, as well as ensuring transparency in the supply chain.

At Sedef, we understand that product integrity is a shared responsibility among all supply chain partners, just like food safety and animal welfare. To take our commitment to the next level, we collaborated with relevant stakeholders to develop a Dutch Chain of Custody standard for pork, certified under the ‘Beter Leven’ standard of the Dutch animal welfare trust in 2015. This coincided with the retail-wide introduction of ‘Beter Leven’ pork in the Netherlands.

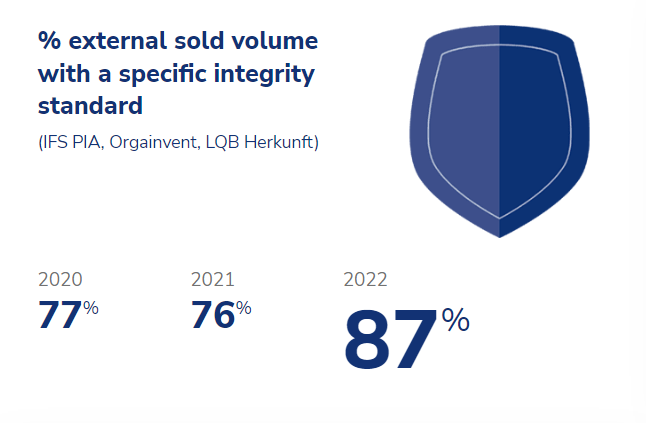

Our integrity assessments require evidence of how Sedef ensures and verifies mandatory and additional product-related information. By 2022, our goal is for 85% of our sales volume to originate from plants certified according to specific product integrity standards. This demonstrates our commitment to maintaining the highest levels of product integrity in all aspects of our business.

During 2021, we further implemented modernised software systems and cloud solutions in our pork production plants. We did this in order to optimise the data flow in a more precise, efficient way and to be able to make product balance calculations in more detail.

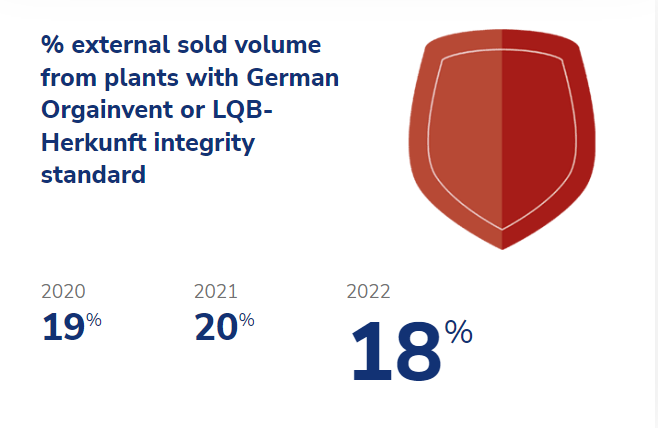

Within the north-western European market, consumers and customers are increasingly demanding to know the origin of their meat. For example, several Dutch and German retailers demand meat originating from a limited number of pig farms. There are groups of Dutch pig farms, certified as Beter Leven 1-star, which are associated with a specific retailer. We make sure that these individual supply chains are dedicated to one customer. These retailer-specific supply chains are also a good opportunity to demonstrate full transparency to consumers and citizens

DNA is the ultimate consumer-care check and also an instrument to show the integrity of all our processes

In the last few years, the integrity of our products and processes have become more important for our customers and consumers. By ‘integrity’, we mean that all attributes associated with the product, including animal welfare and origin, can be 100% verified. We have already implemented process integrity control systems with verification by product, balanced throughout the whole supply chain. In addition to these certified systems, we have now added the monitoring of product integrity through the DNA testing of consumer products.

We have organised the process so that DNA from all pork provider sows is collected, analysed, and stored in a DNA data bank. DNA tests are conducted to verify that consumer goods such as pork chops, fresh sausages, cooked meat products, and pork meal components all comply with the pig of origin. In short, DNA is the ultimate consumer-care check and also an instrument to show the integrity of all our processes. With this instrument, Sedef can demonstrate that it is actively ensuring its product integrity.

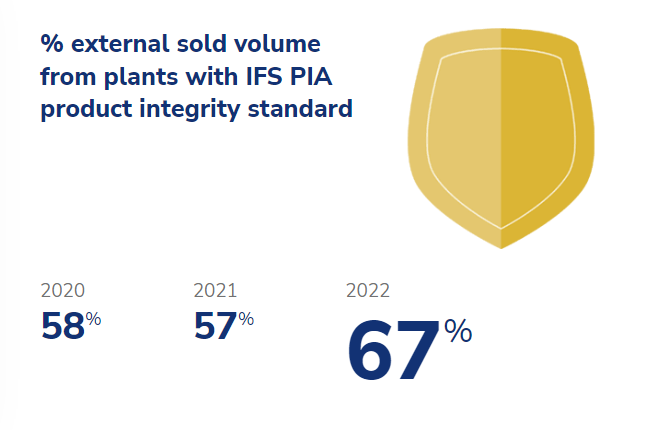

When the sustainable market concept ‘Varken van Morgen (Beter Leven 1-star)’ was developed for German retail a few years ago, with additional requirements for animal welfare, animal health, and environment, it was agreed with retail that the integrity of these products should be guaranteed during processing. The CBL chain of custody standard was used to control and prove product and process integrity. During 2019, Vion prepared to move from the CBL chain of custody to the IFS PIA (IFS Product Integrity Assessment). In 2020, all German Sedef meat production plants, as well the first two production plants in Netherlands, have successfully passed the IFS Product Integrity Assessment.

© 2010 – 2023 Sedef SA. All right reserved.